Examples of countermeasures for electrostatic destruction

Preventing static electricity during wafer testing

Reliable static elimination is possible in wafer testing environments by installing a feedback sensor near the target to enable constant monitoring of the target area.

Eliminating static when peeling protective film from wafers

Static electricity can be eliminated quickly over a wide area. Recording static elimination results during peeling makes it possible to identify the cause of problems.

Static electricity prevention during die bonding

Using high-speed static elimination to prevent discharges during die releasing helps reduce maintenance that would otherwise be necessary with conventional devices.

Test handler ESD protection and quality assurance

With a high-performance ion balance of ±1 V, the device can be used safely in any semiconductor manufacturing site. Previous static elimination results can also be checked to identify affected periods in the event of a problem.

Static elimination during wafer inspection

Airless and energy-saving ionizers help reduce air consumption in a factory while ensuring advanced static elimination performance.

Preventing ESD during PCB inspection and quality assurance

Electrostatic discharge can be prevented during PCB inspection to reduce the risk of defects during product assembly or after shipment even for products that have already passed inspection.

Localised elimination of static and dust in air vacuum equipment

Static elimination can still be performed using a tube even in equipment with no space for installation of an ionizer.

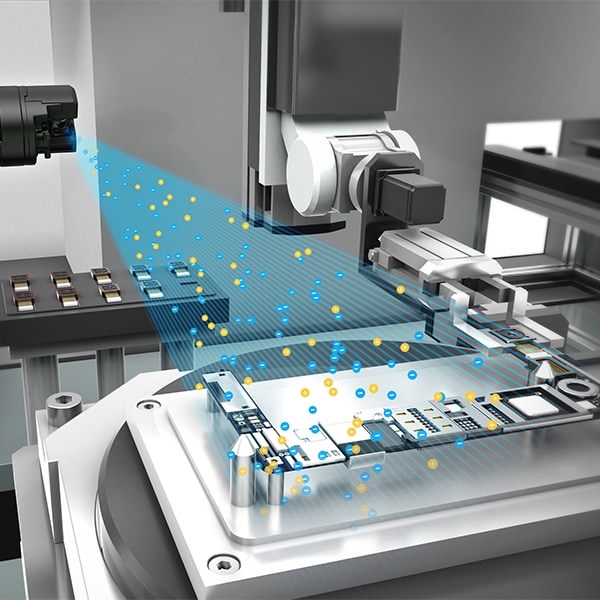

Preventing ESD damage during camera module assembly

The ultra-compact design and 360-degree directionality make it possible to eliminate static just about anywhere.

Static elimination of reel winders prior to mounting

Airless and energy-saving ionizers help reduce air consumption in a factory while ensuring advanced static elimination performance.

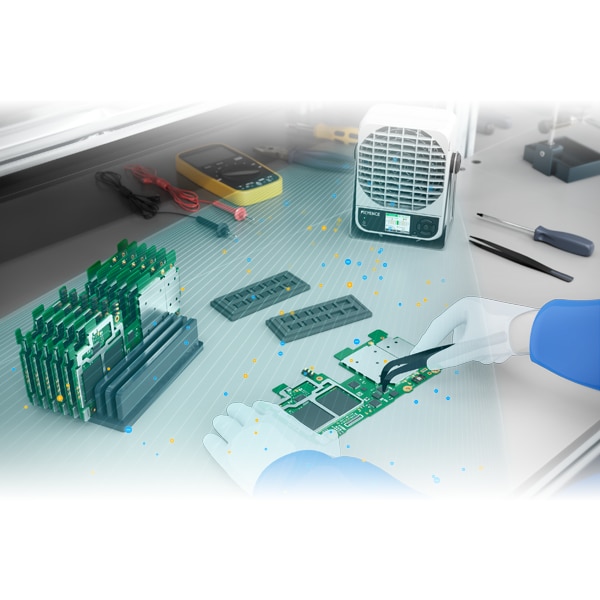

Eliminating static charge in workspaces

Static electricity is a common problem in manual workspaces. Even grounding and other countermeasures are usually insufficient to eliminate the static problems that occur. Using an ionizer can be the solution that makes the difference.

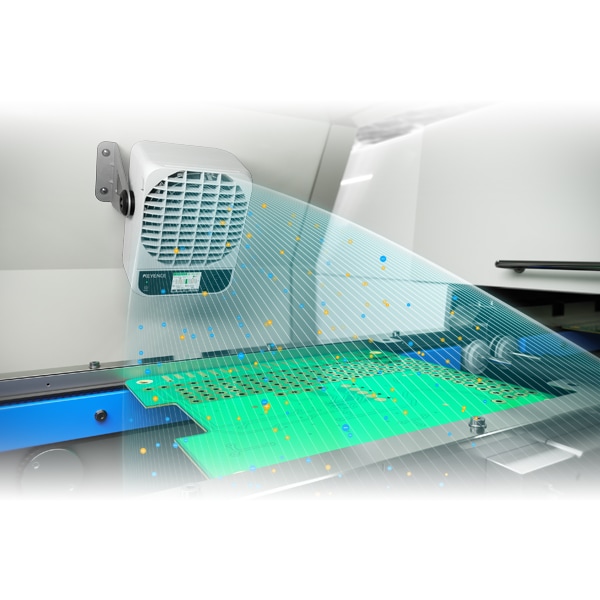

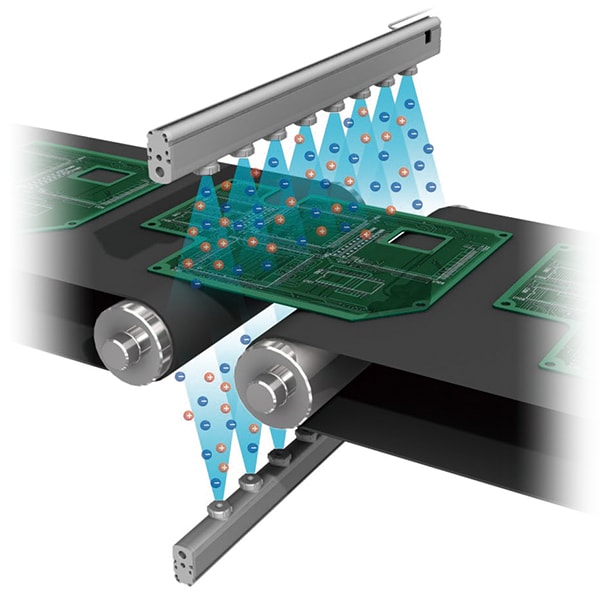

Preventing ESD during the transport of PCBs

During transport, PCBs become statically charged due to contact and separation from conveyor belts. Strong charges can lead to electrostatic destruction and adhesion of foreign particles, which in turn can lead to manufacturing defects. An ionizer can reduce these defects by eliminating the electrostatic charge.

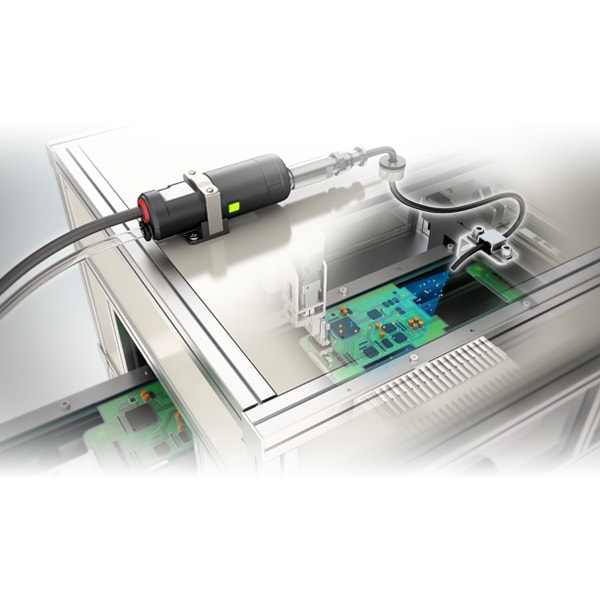

Preventing electrostatic destruction of electronic PCB testers

A foreign object between the probe and the PCB during conductivity testing is considered a conductivity defect and means the test has to be repeated, greatly reducing the yield. Sensitive probes can even be damaged by the static electricity. An ionizer can eliminate these problems.

For more information, please contact KEYENCE.