Observation and Measurement of Probe Cards and Contact Probes

The spread of fifth-generation mobile communications systems (5G) and the products supporting it, have further boosted the advancement of smaller and denser semiconductor devices. At a result, the inspection and analysis of various electronic components, such as integrated circuits (ICs) and large-scale integrated (LSI) circuits, require increasingly higher accuracy.

This section reviews the basics of probe cards and contact probes, which are instruments used for the inspection of semiconductor devices, and includes examples of how digital microscopes are used to achieve the required accuracy.

- What Is a Probe Card?

- What Is a Contact Probe?

- Service Lives of Probe Cards and Contact Probes

- Observation and Measurement Examples of Probe Cards and Contact Probes

- A Digital Microscope That Improves Inspection of Probe Cards and Contact Probes

What Is a Probe Card?

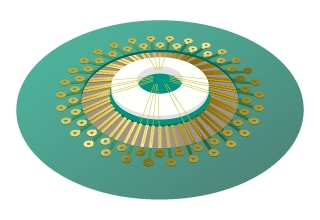

A probe card is an instrument used in the inspection process of silicon wafers during front-end LSI manufacturing. A probe card consists of a circular printed circuit board (PCB) with attached probe pins or probe needles.

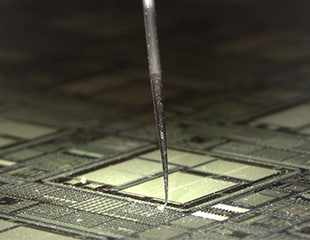

Each LSI chip, fabricated on a wafer, is electrically inspected with the simultaneous contact of multiple probe pin tips arranged on the PCB. Probe cards detect opens and short circuits and also measure electric current and high frequencies. A probe card is usually attached to the prober of a wafer tester and, during inspection, brought into contact with a wafer chip on a stage from above.

Representative types of probe cards

Probe cards can be classified according to their structure including the probe alignment and probe fixation. Two representative probe cards and their characteristics are shown below.

Vertical (advanced) probe card

A vertical (advanced) probe card consists of a PCB and an attached block to which perpendicular probes are affixed. With this type, probes can be aligned in a grid or aligned to measure multiple chips. Maintenance is easy because probes can be replaced individually. Also, dents can be minimised, causing no damage to solders. However, the manufacturing costs are relatively high, which is not really suitable for aluminium electrode pads (Al pads) on wafers.

Cantilever probe card

A cantilever probe card has needles made from tungsten and similar materials. These needles are directly fixed on a PCB.

This type can be manufactured at costs lower than the vertical type. Its probes can also be aligned at smaller pitches, supporting Al pads. When compared to the vertical type, the cantilever type has greater restriction on pin alignment and generates larger dents. This type also requires operators to spend time and effort for periodic maintenance such as repair and adjustment (such as height adjustment).

What Is a Contact Probe?

A contact probe is an inspection instrument used for continuity inspection by contacting the electrodes of various electronic components. Contact probes are widely used for inspection of electronic components. Various electronic components, such as semiconductors, liquid crystal panels, bare boards, PCBs, connectors, capacitors, sensors, and batteries, can be inspected using contact probes.

Contact probes are used not only in continuity checks but also to collect data for behaviour inspections of components in circuits (in-circuit tests) and for function tests. Contact probes are used to detect opens and short circuits, measure high frequencies, check impedance (resistance), and check parameters of components in circuits.

Structure of a contact probe

A contact probe consists of a barrel and, in the barrel, a spring and plunger. The connection resistance in the barrel can be stabilised by optimising the spring pressure in the barrel. Typical contact probes contain parts plated with gold to prevent corrosion and decrease the contact pressure of sliding sections.

The required number of contact probes are pressed into a resin jig designed for the inspection target, and the plunger tips are brought into contact with this target. This instrument is highly maintainable because it can be used repeatedly simply by replacing the worn probes in the jig.

- A

- Contact probe

- B

- Barrel

- C

- Spring

- D

- Plunger

- E

- Jig

- F

- Inspection target

Plunger tip shapes of contact probes

The shape of the contact tip differs according to the shape of the inspection target such as electrodes and terminals. Using a plunger with the optimum tip shape prevents damage to fragile targets during inspection. Representative shapes and applications are introduced below.

Round

This tip is used for inspection where damage to fragile electrodes, such as those on flexible printed circuits (FPCs), must be avoided.

Conical

This tip is mainly used to inspect lands and pads on PWBs.

Flat/Concave

A flat tip is used to prevent damage to electrodes or when the tip needs to contact an area on inspection targets.

A concave tip is used to contact the convex shapes of terminals.

Delta cone

A delta cone tip is used to inspect concave shapes such as through holes on PWBs.

Crown

This shape is used to inspect the leads of mounting components and convex shapes by contacting with multiple probes.

Service Lives of Probe Cards and Contact Probes

Service lives of probe cards

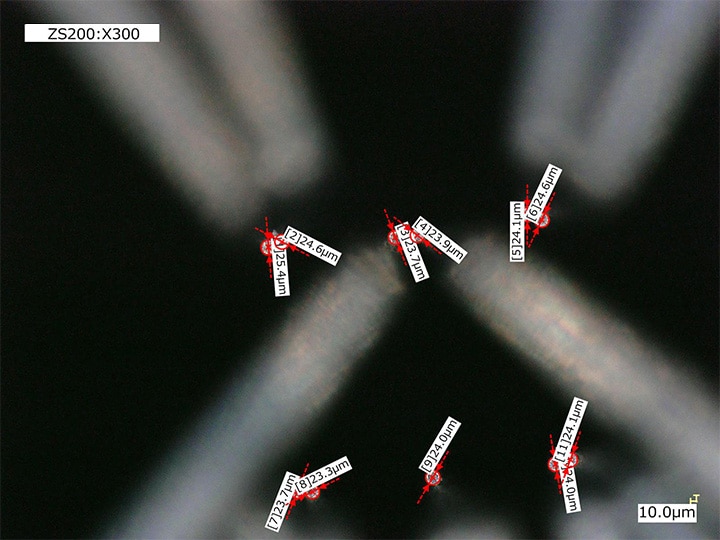

When a probe card is used to inspect LSI chips, multiple sharp and microscopic probe pins are brought into contact with chip terminals on wafers. Some small probe cards, in the size of a few cm², have several thousand probe pins aligned at small pitches from 20 to 30 μm. Probe cards, which are very elaborate, have service lives that are determined by the number of times probe pins contact chips on wafers. Typical probe cards are said to reach their service lives after performing up to several million contacts.

When fabricating an enormous amount of chips using a large number of wafers, it is very important to understand the probe pin conditions to maintain product quality. Worn or abnormal probe pins can lead to the acquisition of incorrect inspection data, causing good chips to be rejected and decreasing the yield rate.

Service lives of contact probes

The service lives of contact probes vary depending on the resistance, environment, and heat applied to the leads during inspection. Typical contact probes mechanically withstand approximately one million contacts.

This durability, however, varies depending on the inspection conditions. One item that is important in determining if a contact probe has reached its service life is to understand the shape of the plunger tip that contacts inspection targets. During inspection, worn tips can generate variations in resistance and cause false judgement, affecting the quality control and yield rate.

Observation and measurement of probe cards and contact probes

Probe cards and contact probes both have contacts with microscopic shapes. To prevent inspection errors that can cause defective products to be overlooked or reduce the yield rate, periodic magnified observation and measurement are important in determining if instruments have reached their service lives due to wear or other reasons.

The observation and measurement of probe cards and contact probes can be difficult with conventional microscopes due to the size and three-dimensional aspect of the parts. For example, contact measuring systems are using probes too large for the part, causing multiple probe pins aligned at small pitches to be contacted simultaneously.

Read on for an introduction to the latest examples of observation and measurement using our 4K digital microscope that solves these problems.

Observation and Measurement Examples of Probe Cards and Contact Probes

There are many issues in observing and measuring the microscopic shapes of probe card pins and contact probe plunger tips but is critical to understand damages, such as wear, because the shapes heavily affect inspection accuracy.

With KEYENCE's VHX Series digital microscope, users are able to easily capture high-resolution images and accurate measurements at the push of a button. See below for examples on how the VHX Series has been used to improve the inspection process of probe cards and contact probes.

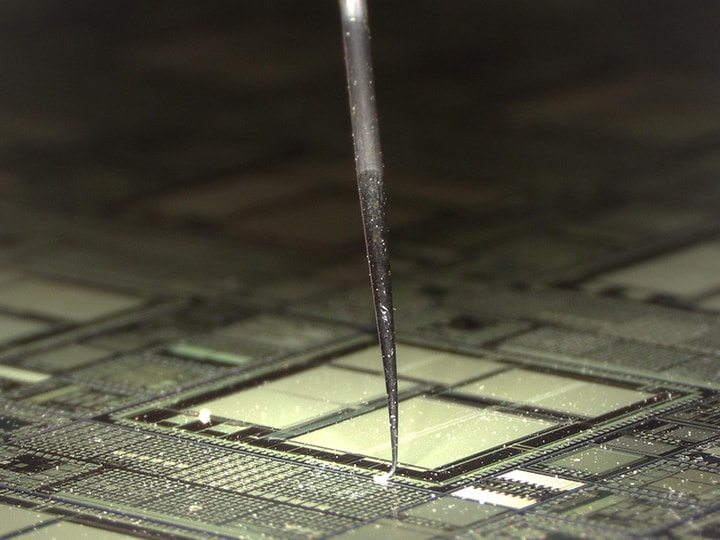

Observation of probe card pin contact and tilted observation

The VHX Series digital microscope combines a large depth of field and free-angle observation system, allowing users to capture high-resolution images at any angle.

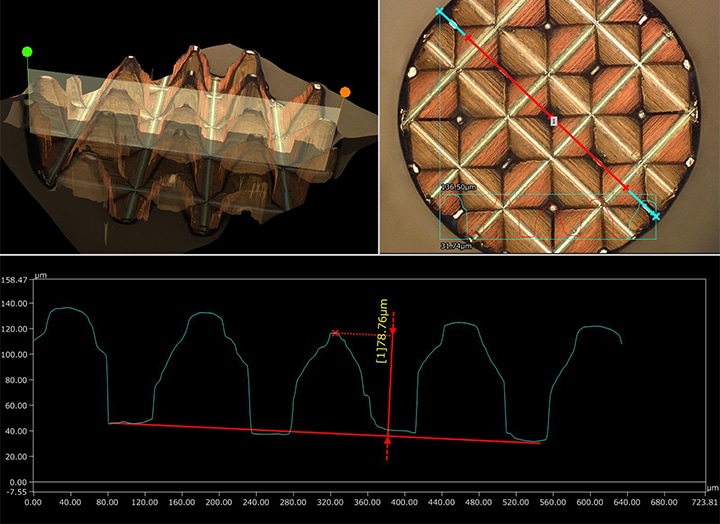

Outer diameter and height measurement of probe card pins

The VHX Series digital microscope can capture accurate 2D and 3D measurements without touching the target.

2D/3D measurements, such as two points, parallel lines, height, and areas, can easily be taken by selecting the specified locations on the image. For instance, users can easily measure the outer diameter of the probe pin tips to understand wear in seconds or draw a virtual cross section to measure the height of the pins.

All of the images and measured values can be automatically exported to a report to help understand tendencies in the wear and deformation process.

High-magnification observation of contact probe tips

The plunger tips of contact probes, which have microscopic three-dimensional shapes, wear out easily because they come in contact with targets during inspection. High-magnification observation of these targets often has a trade-off between requirements and conditions, resulting in, for example, partial focusing on the target and reductions in resolution.

The VHX Series 4K digital microscope combines a large depth of field and high resolution to capture fully-focused images of microscopic wear and chipping of plunger tips even at high magnifications.

Because the inspection instruments are made of metal, it takes a lot of time and effort to determine the lighting conditions due to the effects of diffused reflection. The VHX Series is equipped with the Multi-lighting function, which automatically acquires image data captured with omnidirectional lighting at the press of a button. Operators can promptly start observation simply by selecting the image suitable for the purpose, which significantly reduces the time required for lighting condition determination.

Additionally, the lighting conditions used when a past image was captured can be fully reproduced just by selecting that image. This increases the operation speed even when wear of multiple plunger tips needs to be observed under the same conditions.

3D display and profile measurement of contact probe tips

The VHX Series digital microscope captures multiple images at different focus positions and instantaneously combines them into a single image, even at an angle, to easily view a sample in 3D and capture 3D measurements.

Easily perform non-destructive profile measurements at the click of a button with the VHX Series. By utilising the advanced functions, surface irregularities can be measured at sub-micrometre levels and the degree of wear can be accurately understood regardless of size and shape.

A Digital Microscope That Improves Inspection of Probe Cards and Contact Probes

The VHX Series digital microscope streamlines the research and development and quality assurance of probe cards and contact probes, allowing users to easily capture high-resolution images, accurate measurements and automatically create reports! For additional product info or inquiries, click the buttons below.