Advanced Observation and Measurement of Ampoules and Vials

Ampoules and vials are solution containers widely used at medical sites to store solutions for use in injections and to fill syringes. These glass containers require high airtightness and reliability, and their quality is closely related to the preservation and safety of the solutions they store.

This section introduces basic knowledge relating to ampoules and vials, precautions regarding their quality, and the latest observation and measurement examples using a 4K digital microscope effective in the quality management and quality assurance of ampoules and vials.

- What Is an Ampoule?

- What Is a Vial?

- Observation and Measurement Examples of Ampoules and Vials

- Optimise Ampoule and Vial Quality Control with a 4K Digital Microscope

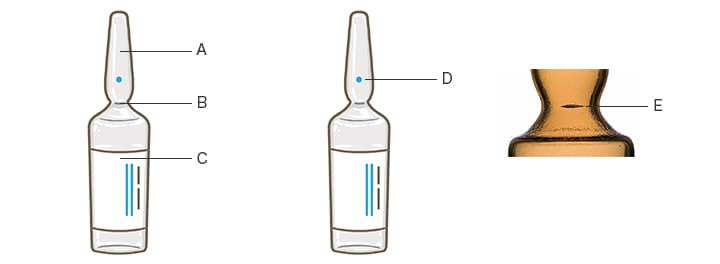

What Is an Ampoule?

An ampoule is a container used to store injection solution. They are said to be the injection solution container with the lowest cost and highest airtightness. After the solution is poured into a glass cylinder, the tip of the container is melted and sealed to manufacture an ampoule. When it is time to administer the injection solution, the person administering the solution breaks the tip of the ampoule to open it. A hypodermic needle is then inserted into the opening to suck out the solution into a syringe. Recently, containers known as one-point-cut ampoules have become mainstream. They are processed to have a cut-line allowing the tip to be broken easily, facilitating easy opening. Mainly they are used as containers for small amounts of solutions, and some use coloured glass to shield against light.

- A

- Tip

- B

- Neck

- C

- Body

- D

- Point mark

- E

- Cut-line

Precautions regarding ampoule quality

- Ampoules must be carefully cleaned to prevent contamination by foreign particles. Also, the ampoule must be filled with liquid medicine that is clear and bright, and the ampoule must then be melted and sealed.

- Breaking the tip to open the ampoule for use may create microscopic glass fragments that contaminate the injection solution. To ensure ampoules can be opened safely, caution must be exercised regarding the processing quality of their cut-lines.

- Air bubbles, cracks, breakage, etc. in the glass will negatively affect the storage quality of the ampoule and the quality of its contained solution. To prevent defective products from being released, it is necessary to identify and eliminate the causes of defects by inspecting the appearance of products and by performing magnified observation prior to shipping.

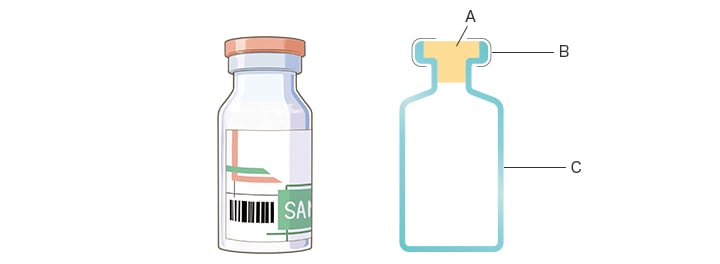

What Is a Vial?

A vial (or vial bottle) is a container used to store injection solution. After a sterile wide-mouth glass container is filled with the solution, the container is capped with a rubber stopper then wound and tightened using an aluminium cap or other method.

The rubber stopper can be pricked repeatedly to extract the solution from the vial into a syringe. Therefore, the solution can be collected several times.

One example application is diluting the solution in a vial with the saline solution taken from an ampoule when giving an injection. To prevent contamination in this procedure, it is necessary to use separate hypodermic needles.

- A

- Rubber stopper

- B

- Aluminium cap

- C

- Sterile glass container

Precautions regarding vial quality

- When a hypodermic needle pierces the rubber stopper, pieces of the stopper may be shaved off and enter into the solution as foreign particles, causing coring. This problem normally does not occur so long as the proper method is used to prick the stopper. However, caution is necessary because poor rubber stopper quality or errors during capping may lead to coring regardless of the technique with which the stopper is pricked.

- During the administration of an injection, the doctor visually checks for contamination with foreign particles after the solution is diluted, but the basic assumption is that unopened vials do not contain foreign particles. If a vial is contaminated with foreign particles during manufacturing, the quality and safety of the liquid medicine will be compromised, so caution is necessary regarding foreign particles affixing to the bottle or rubber stopper during filling or capping.

- Glass container defects such as cracks, scratches, air bubbles, and black spots may decrease the container’s preservation and affect the quality of the contained solution. Detailed appearance inspections are required to prevent these defects and to identify their causes and prevent them from reoccurring.

Observation and Measurement Examples of Ampoules and Vials

Borosilicate glass is commonly used as the material for ampoules and vials. Glass container defects such as cracks, scratches, and air bubbles may affect the quality and safety of the solution, so precise observations and evaluations using a microscope are required not only in automated 100% inspections, but also in the work of quality management and assurance.

However, glass has characteristics such as transparency, permeability, and diffuse reflection of light, leading to the issue that it is very difficult to check processing locations and to perform magnified observation and measurement of microscopic appearance problems.

KEYENCE’s ultra-high accuracy VHX Series 4K digital microscope is equipped with a cutting-edge, high-resolution HR lens; a 4K CMOS image sensor, and an observation system that provides access to diverse functions with simple operations. The VHX Series optimises observations and measurements and improves their sophistication by allowing for observation with clear 4K images and for non-contact 2D and 3D measurement.

Read on for examples of observation and analysis of glass containers—ampoules and vials—using the VHX Series.

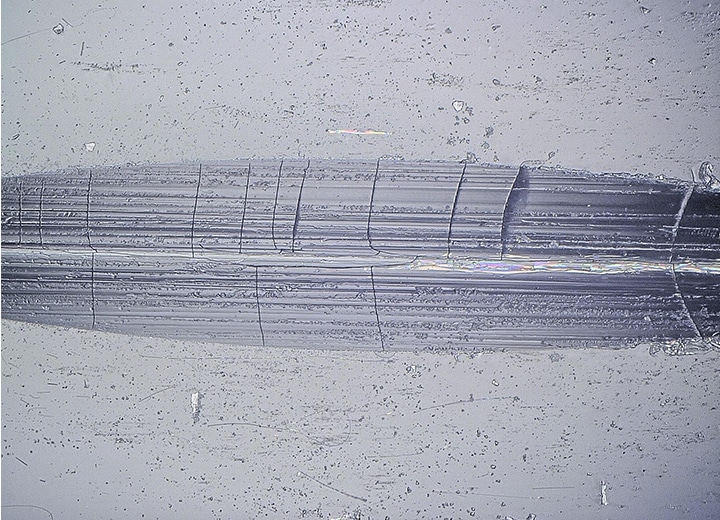

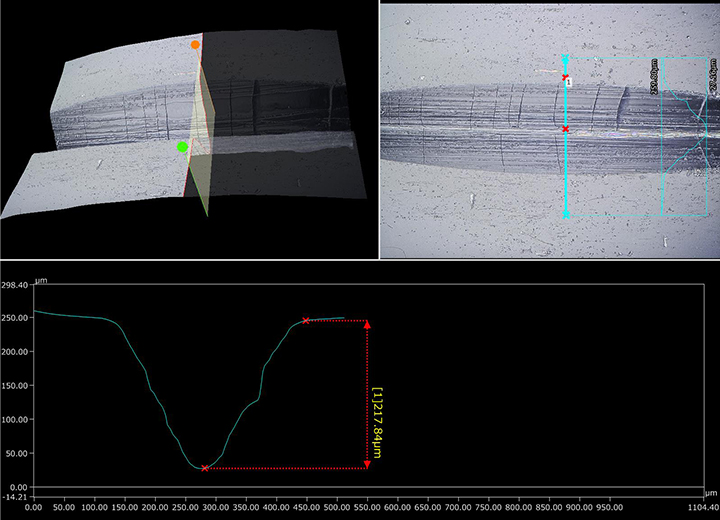

Observation and 3D measurement of the cut-line on an ampoule

The VHX Series enables quick and clear observation of glass by incorporating the Multi-lighting function. Multi-lighting captures multiple images of the sample under different lighting conditions and displays them all on the screen. The user simply needs to select the best image, and appropriate lighting will be used to observe the sample.

This product is also equipped with a High Dynamic Range (HDR) imaging function that combines together multiple images at varying shutter speeds to acquire an image with high colour gradation. This function enables glare-free, high-accuracy, and high-contrast observation of the textures of ampoule cut-lines, which were difficult to observe until now due to their low contrast against the background, and is effective in observing microscopic cracks in glass containers.

Furthermore, the VHX Series is capable of stacking multiple images in the Z-direction, allowing it to capture and display 3D images that show texture and roughness. The result is that the 3D image displayed on the screen can be rotated to any angle for observation without having to move the sample on the stage or change the angle of the lens.

Profile measurement can also be performed simply by selecting arbitrary points. Sub-micrometre level measured values can be acquired for cross-section shapes and surface irregularities of cut-lines in a non-destructive, non-contact manner.

Observation of ampoule and vial defects

Defects and flaws such as cracks, fractures, and air bubbles in glass containers that require high airtightness impair product durability, safety, and reliability. However, these defects are three dimensional due to the thickness of the glass, so it was difficult to observe the entire target clearly with conventional microscopes because only a part of the target could be brought into focus under high-magnification observation.

The VHX Series 4K digital microscope is equipped with an optical system that combines high resolution with a depth of field that is at least 20 times larger than optical microscopes. Hence, it enables observation with high-accuracy images in which the entire target is in focus even if that target is thick. Even microscopic fractures and air bubbles deep within the glass can be clearly observed.

Optimise Ampoule and Vial Quality Control with a 4K Digital Microscope

With its high performance and diverse functions, the VHX Series 4K digital microscope improves the sophistication and efficiency of the quality management and quality assurance of glass containers.

Conventionally, observing glass was difficult due to its transparency and ability to scatter light and finding focus and adjusting the lighting conditions was time-consuming. The VHX Series automates nearly the entire process, enabling users to spend more time inspecting containers, and less time making adjustments to the microscope.

Furthermore, the VHX Series is able to capture 3D images, enabling defects within the glass and cut-lines to be observed and measured.

For additional info or inquiries about the VHX Series, click the buttons below.