Medical Device Quality Control and Assurance

The history of the development of medical technology is also the history of the miniaturisation of medical devices. These days, inspections with higher accuracy than ever before are required. High-standard quality control and quality assurance are especially required for medical devices that are used directly on the human body.

This section introduces inspection examples using KEYENCE's latest 4K digital microscope, which—in response to the requirements for medical devices—enables the capture of clear images and fast measurements.

- Quality Assurance of Advanced Medical Devices

- 4K Digital Microscope Application Examples in Medical Device Inspection and Quality Control

- A 4K Digital Microscope That Meets The Highest Requirements

Quality Assurance of Advanced Medical Devices

Because most medical devices are used directly on the human body, the devices have high-level requirements for safety, functionality, and effectiveness. Strict quality control and quality assurance are essential especially for medical needles, catheters, stents, pacemakers, and other such products that are used within the body because microscopic scratches, burrs, and similar defects have a high chance of damaging the human body or putting the patient's life in danger.

Manufacturers and vendors of medical devices or in vitro diagnostics are required to conform with a Quality Management System (QMS), which is a standard related to the manufacturing control and quality control of the products. Quality assurance is realised by meeting strict inspection requirements that conform to the QMS standard in all steps of the procedure, from raw materials to the manufacturing process to the shipping of the final product.

4K Digital Microscope Application Examples in Medical Device Inspection and Quality Control

As medical treatment becomes more advanced, so too do the requirements for the functionality of medical devices and the requirements for the inspection and analysis of products. Extremely high-level inspections and analyses that make use of optical microscopes and digital microscopes are required not only in product manufacturing, but also in research and development.

KEYENCE has manufactured digital microscopes for over 20 years, with each generation containing new solutions to ever-evolving customer applications. The VHX Series 4K Digital Microscope is our latest generation and represents a new era for the product.

This section introduces the latest applications of inspections and analyses of medical devices using the VHX Series to realise advanced quality control and quality assurance.

Catheter inspection

Balloon catheter inspection

The VHX Series 4K Digital Microscope realises a deep depth of field with its newly developed high-resolution HR lens, 4K CMOS sensor, and depth composition. This depth of field makes it possible to fully focus the image of the entire target in inspections of three-dimensional balloon catheters. With conventional microscopes, only a part of the image could be brought into focus at a time.

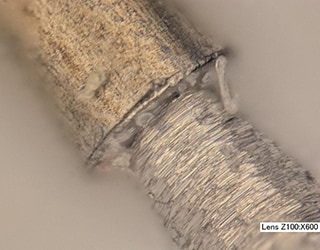

Guide wire inspection

The VHX Series 4K Digital Microscope is equipped with a High Dynamic Range (HDR) function that expresses high colour gradation with 65000 or more colours by capturing multiple images with different shutter speeds. This function enables observation with high definition and high contrast even of microscopic locations on guide wires, which could not be viewed until now.

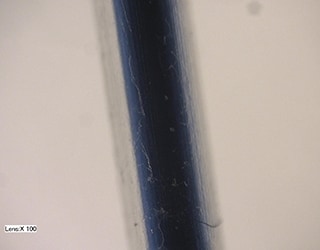

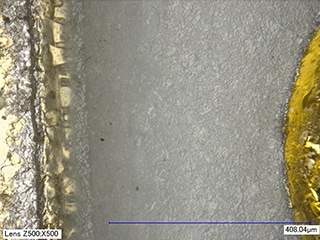

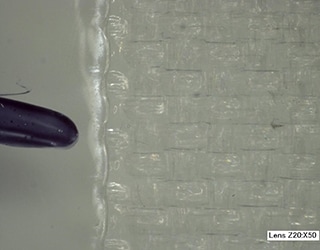

Hydrophilic coating inspection

A hydrophilic coating is an important piece of technology that provides guide wires and similar objects with lubrication inside veins. However, with conventional microscopes, it is extremely difficult to observe and inspect targets with hydrophilic coatings due to the faint colour tones.

With the VHX Series 4K Digital Microscope, hydrophilic coatings can be easily observed due to the HDR function and high-definition 4K images. The coating film thickness can also be measured with the VHX.

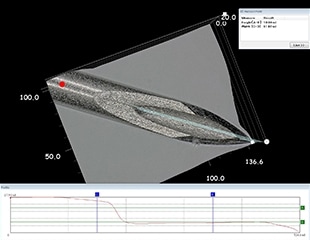

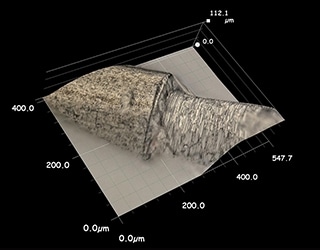

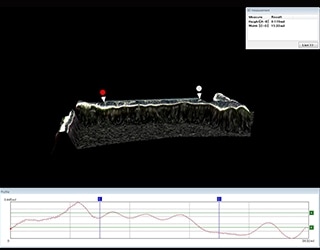

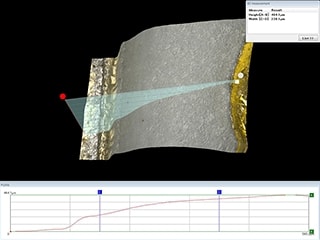

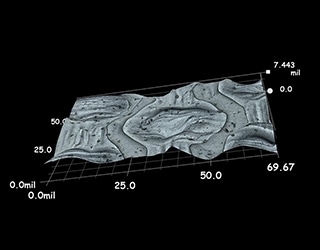

3D shape measurement and appearance inspection of a catheter surface

With conventional microscopes, it is not possible to obtain fully focused images on targets that have uneven surfaces, like catheters.

With the VHX Series, depth composition is performed to capture fully focused images, even at high magnifications.

During the depth composition process, 3D height data is automatically captured. This allows a single VHX unit to be used for visual inspection, 2D measurements, and 3D profile measurements of scratches and defects.

Medical needle inspection

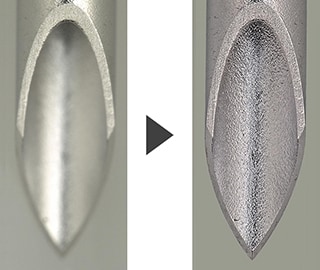

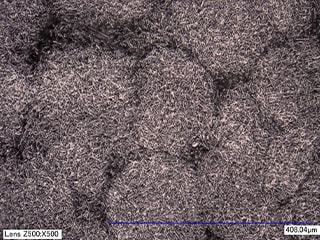

Medical needle tip observation

With conventional optical microscopes, it was only possible to bring a part of the image into focus at the high magnifications required for the observation of the outer appearance of medical needle tips.

The deep depth of field of the VHX Series 4K Digital Microscope makes it possible to quickly and easily obtain fully-focused images even in the high magnification observations of needle tips, which have three-dimensional shapes.

Also, the HDR function can quickly obtain an image with high colour gradation by obtaining multiple images at varying shutter speeds, thereby enabling observation at high levels of definition and contrast.

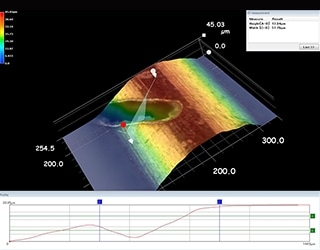

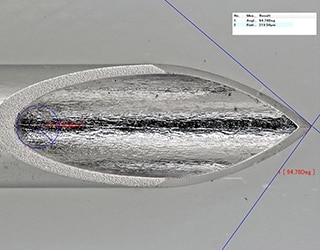

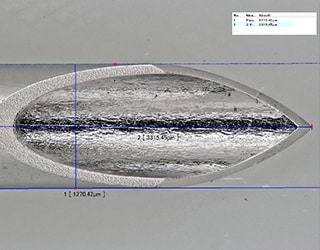

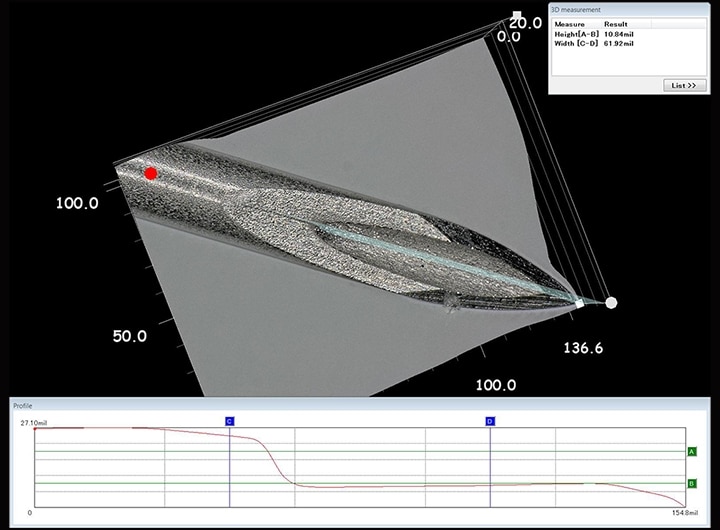

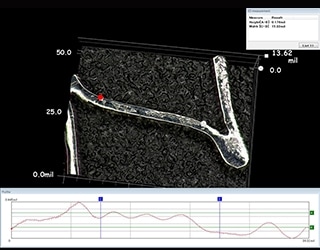

Medical needle tip shape inspection

Conventionally, in addition to microscopes, it was also necessary to use various measurement systems to measure medical needles, which took a large amount of time and effort due to the increased number of inspections.

With the VHX Series 4K Digital Microscope, 2D measurement can be performed directly from observation. Various tools can be used to easily and quickly perform different types of measurements such as angle and width measurements.

3D measurement is also possible, enabling the inspection of the detailed shapes of medical needle tips by displaying the 3D shape and measuring the profile. This one unit is all that is needed to perform visual inspections, take 2D and 3D measurements, and record numerical values for reporting.

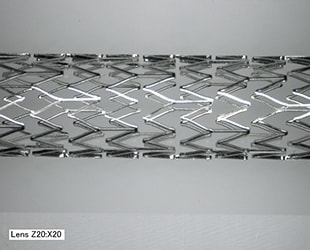

Stent inspection

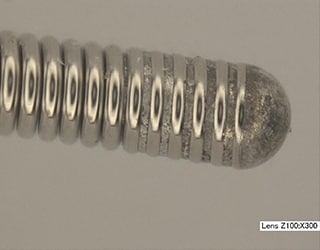

Stent free-angle observation

Using the free-angle observation system and the high-accuracy XYZ motorised stage of the VHX Series 4K Digital Microscope enables stent observation from a wide variety of angles, which is not possible with conventional microscopes.

The VHX Series is equipped with adjustment mechanisms that allow for easy field-of-view alignment, rotation, and oblique axis motion. Eucentric design ensures that the target stays centred in the field of view, even if the lens is tilted or rotated, thereby making it possible to easily observe stents—which are three dimensional and have complicated shapes—from a variety of angles.

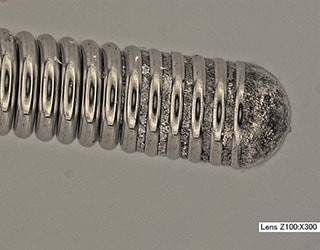

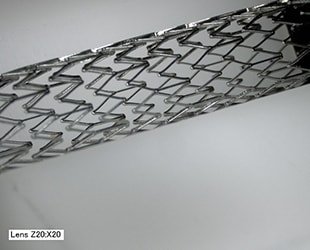

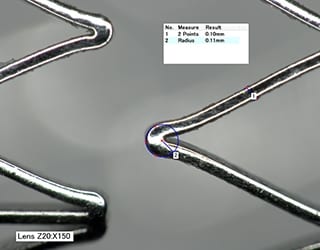

Stent strut bend radius measurement

The VHX Series 4K Digital Microscope uses high-resolution 4K images to perform 2D measurements not previously possible with conventional microscopes. The stent strut bend radius can be measured non-destructively using the built-in measurement tools.

The glare and ring-reflection removal functions can be used to eliminate the reflections from the metal surface that is typically seen on the surface of stents. Furthermore, the HDR function can be used to obtain images with high colour gradations, enabling inspection of defects such as strut fractures.

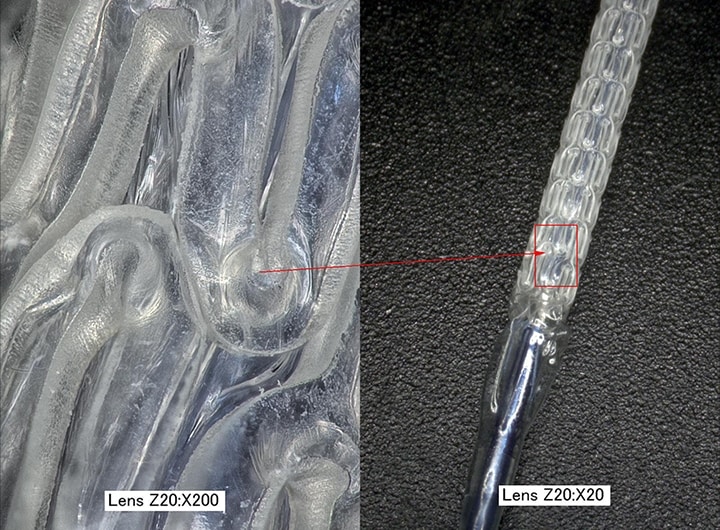

Bioabsorbable stent inspection

The VHX Series 4K Digital Microscope can accurately observe bioabsorbable stents by minimising reflections. Subtle fractures and other such defects can also be detected by using high-resolution 4K images to perform appearance inspections at high magnifications.

Furthermore, 3D shape and profiles measurements can be obtained quickly, so defects in strut appearance can be accurately measured and analysed.

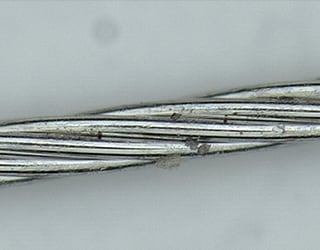

Implant wire inspection

Implant wire observation and measurement

Implant wires can be easily observed and inspected due to the large depth of field of the VHX Series.

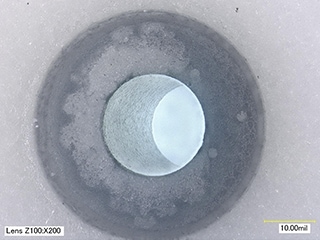

Pacemaker failure analysis

Pacemaker component inspection

The VHX Series 4K Digital Microscope can be used to observe defects in pacemaker components such as fractures and cracks with clear, 4K images. Also, by combining the free-angle observation system and backlighting, side walls of holes can also be inspected quickly and easily.

In high-magnification observation, conventional microscopes can only observe a portion of the target due to their shallow depth of field.

With the VHX Series, real-time depth composition makes it possible to obtain fully-focused and clear images of the entire target instantaneously. Because such images are automatically obtained, users are freed of the hassle of adjusting focus, leading to rapid efficiency improvements.

Pacemaker Component 3D Shape and Profile Measurement

Another advantage the VHX Series has over SEMs is the ability to create 3D images by obtaining height information. These 3D images enable 3D shapes and profiles to be obtained from high-magnification images.

Packaging inspection

Resin packaging appearance inspection

Packaging defects affect the protection, preservation, safety, and reliability of the products contained within. Packaging inspection is one of the final steps in quality assurance before the product is shipped.

By using polarising illumination, the VHX Series 4K Digital Microscope can minimise reflections from films and package surfaces made of plastic, enabling accurate appearance inspections.

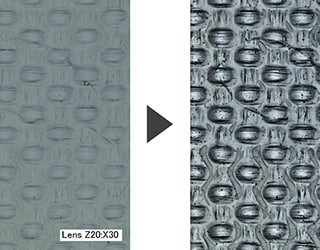

Plastic Packaging Magnified Observation and Measurement

High-magnification observation of packaging using materials made of plastic can be difficult because it is hard to focus the image.

The VHX Series 4K Digital Microscope can use its HDR function, which obtains images with high colour gradation and high contrast while changing the shutter speed, to observe clear, high-magnification images. The ability to perform accurate measurement using HDR images with easy operations leads to drastic improvements to inspection accuracy and speed.

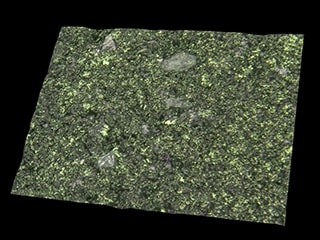

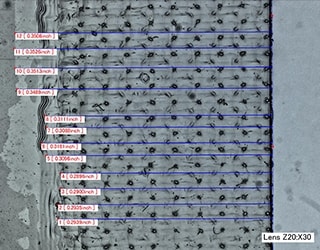

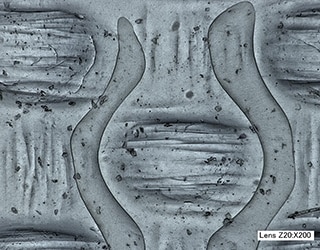

Plastic packaging 3D shape inspection

The deep depth of field and clear HDR images of the VHX Series 4K Digital Microscope make it possible to obtain fully-focused high-magnification images even when the target has an uneven surface. Furthermore, 3D images can be created from these high-magnification images and can be used to visualise and measure 3D shapes, enabling a single VHX Series unit to quickly complete the entire series of tasks that an inspection requires.

A 4K Digital Microscope That Meets The Highest Requirements

The VHX Series enables all quality control and assurance inspections to be performed with a single device. High-magnification observation, 2D and 3D measurements, and inspection reports can all be performed seamlessly, yielding rapid improvements in efficiency.

For additional product info or inquiries, click the buttons below.