Runout / Vibration

High-speed sensors can measure runout of brake discs, regardless of surface finish.

Confocal Displacement Sensor

CL-3000 series

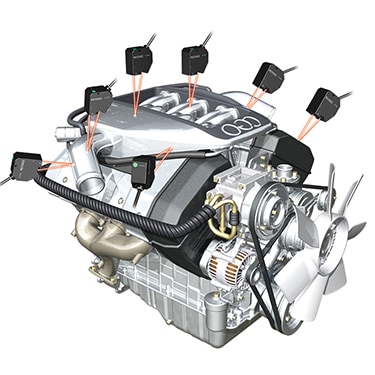

Measure many points on an engine with a multi-point laser system for accurate characterization of engine vibration. With ultra-highspeed sensors, even the smallest vibrations can be detected.

Ultra High-Speed/High-Accuracy Laser Displacement Sensor

LK-G5000 series

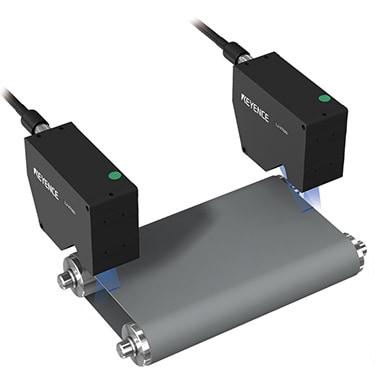

Measure the position and edge flutter of a belt with two 2D laser profile sensors for stable measurement.

2D/3D Laser Profiler

LJ-X8000 series

Measure the extent of foil vibration just before the slit. Even if the target is tilted due to vibration, the good angle characteristics of the CL Series enable stable measurement.

Confocal Displacement Sensor

CL-3000 series

Residual vibration measurement is used to determine how much a robot shakes after stopping. When working with a welding torch or other tool, the measurement location may not always have a flat surface. Using a 2D laser profiler enables accurate measurement on a wide range of surface shapes.

2D/3D Laser Profiler

LJ-X8000 series

Ultra-compact ø8 mm heads make it possible to install multiple heads in narrow spaces. This reduces the amount of work spent designing equipment and the number of parts that need to be purchased to measure multiple points in close proximity.

Confocal Displacement Sensor

CL-3000 series