Case Studies Customer Testimonials — Warpage and Flatness

Case 1: Warpage Measurement of Glass Plates

| Industry | Semiconductors, LCD Industry |

|---|---|

| Application | Warpage Measurement of Glass Plates |

| Model Adopted | LK-G5000 Series |

We used a contact-type measurement system to measure the warpage of glass plates. We had a recurring issue with surface scratching and were searching for a non-contact solution.

We tested laser displacement sensors from several companies and selected KEYENCE's product because one controller can connect multiple sensor heads. The KEYENCE representative was quick to respond to our inquiry and came on-site to demonstrate the functionality.

Customer

CustomerTestimonial

Thank you for using KEYENCE products.

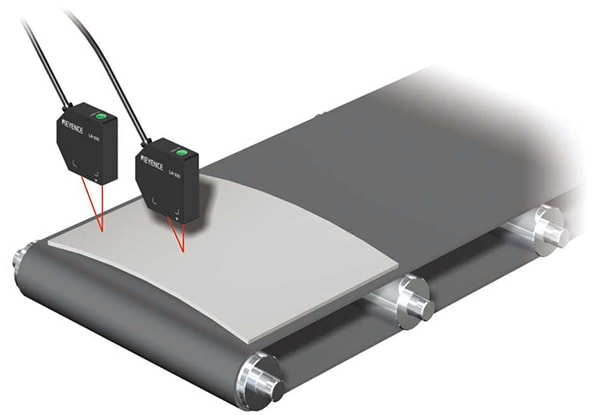

The LK Series Laser Displacement Sensor allows connection of up to twelve sensor heads to a single controller.

Since the customer wanted to measure four sides and a point in the centre of a glass plate, we suggested a configuration of one controller and five sensor heads.

KEYENCE

KEYENCE

Case 2: Warpage Measurement of PCBs

| Industry | Electronic and Electrical Industry |

|---|---|

| Application | Warpage Measurement of PCBs |

| Model Adopted | LK-G5000 Series |

We had been using a typical laser displacement sensor to measure the warpage of PCBs. We consulted KEYENCE because the measured values were not stable and they suggested the LK Series Laser Displacement Sensor.

We used a free trial unit for a week to test the performance and then purchased the product because we saw the value straight away as it resolved our issues.

Customer

CustomerTestimonial

Thank you for using KEYENCE products.

When the target is a PCB, the laser beam sometimes penetrates inside the target and causes stray reflections that make the measured value unstable.

The LK Series Laser Displacement Sensor can suppress the variation in measured values because it features a special mode to allow accurate measurement of targets prone to such laser penetration.

KEYENCE

KEYENCE

Case 3: Warpage Measurement of Building Material Boards

| Industry | Other Manufacturing Industries |

|---|---|

| Application | Warpage Measurement of Building Material Boards |

| Model Adopted | LK-G5000 Series |

Building material boards were visually inspected for warpage. The results were not consistent because the board can look different depending on the ambient light or the individual's judgement criteria.

By adopting the laser displacement sensor, we could establish numeric criteria for judging defective workpieces.

Customer

CustomerTestimonial

Thank you for using KEYENCE products.

The key for stable measurement of targets with rough surface, such as building material boards, is averaging the measured values to suppress variation due to surface condition.

The LK Series Laser Displacement Sensor offers a sampling speed of 392 kHz allowing it to average a large amount of data to achieve stable measurement of even rough surfaces. Calculations between readings can be performed internally to make judgement simple and consistent.

KEYENCE

KEYENCE