Measurement FundamentalsInline/Offline Measurement

Inline measurement and offline measurement refer to different methods of measurement. Inline measurement can also be referred to as “automatic measurement,” and offline measurement can also be referred to as “Manual measurement.” The difference arises from whether measurements in the measurement process (line) are included in the line (inline) or separate from the line (offline).

Inline Measurement

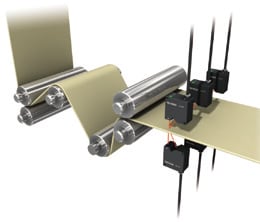

A structure that includes a sensor mounted along a manufacturing line to constantly monitor products passing underneath would be an example of inline measurement.

- 1. Registration of shapes and dimensions (with a tolerance range) for judging product acceptability

- 2. Measurement when a target passes underneath the sensor

- 3. Acceptability judgement

- 4. Output of NG judgement when a product has been determined as unacceptable

Incorporation of the above steps into a manufacturing line enables automatic inspection of mass-produced components.

Inline Measurement Characteristics

With inline measurement, stable measurement that is not affected by the skill of the operator or the measurement methods can be repeated for large amounts of products. In addition, constant monitoring makes it possible to determine when unacceptable products began to appear, which is helpful in managing traceability.

Offline Measurement and Relevant Features

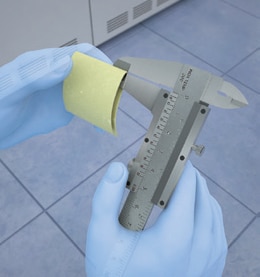

Offline measurement is measurement performed through the manual manipulation of the measurement system in order to obtain measurements for any given point.

While measuring instruments such as vernier calipers and micrometers do allow for measurement at any arbitrary point, measurement results may vary depending on the experience and skill of the person measuring. In addition, because constant monitoring is not performed, it is impossible to determine when unacceptable products began to occur from the statistical data. Determining how often measurements will be performed is an important factor in obtaining stable test results with offline measurement.