3-Axis Hybrid Laser Marker

MD-X series

3-Axis Hybrid Laser Marker MD-X series

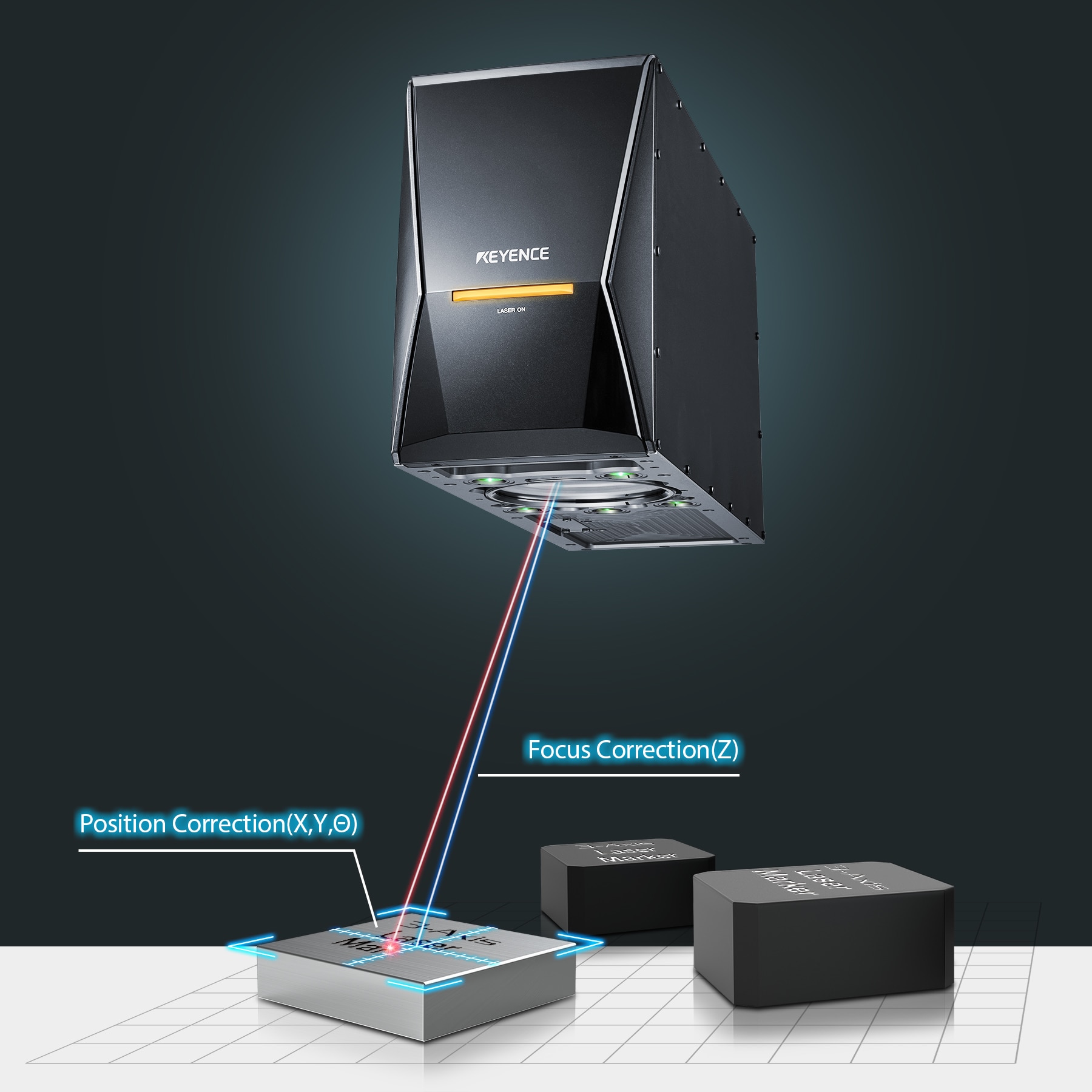

Automatic Focus and Position Correction

A built-in distance sensor constantly measures the distance to the marking location and focuses on that location. By tracking unintentional deviation in the height or inclination of the target, marking defects can be prevented over the entire marking area.

Newly developed hybrid laser

Fast and clear marking on and processing of resins and metals

Applications

-

White + Black Oxidation

Aluminium Castings -

Damage-Free Marking

Carbide Tools -

Contrast Marking

Resin Cases -

Damage-Free Marking

Electronic Components

Features

Full-Field Auto-Focus

Autofocus Anywhere

Mark in-focus on any part, anywhere.

The MD-X laser marker comes standard-equipped with a built-in distance sensor that enables automatic focal corrections. Eliminate manual height adjustments due to part variations in a few simple steps.

Built-In Vision

Mark the same location on any part, anywhere.

The MD-X Series contains a camera inside the laser marking head which can automatically identify a target’s shape. The laser marker can then adjust for X, Y and theta offsets to ensure the marking position is always correct.

The marking system is even able to distinguish between parts and mark each part accordingly.

Data-Driven Analytics

Automatic fault protection and monitoring from anywhere.

The new MD-X uses predictive maintenance to eliminate problems before they occur. In the unlikely event of a marking defect, the laser marker features a wide range of diagnostic tools to identify the root cause and deploy countermeasures.