Barcode Scanners

A rich lineup of code readers that support an ultra-wide field of view, and ultra-long reading depth. These products allow for stable inline reading of barcodes and 2D codes at high-speeds in the logistics and manufacturing industries. The lineup includes a fully automatic tuning type that requires no external lighting so that anyone can easily install, operate, and monitor the readers from nearly anywhere.

Products Lineup

The SR-X Series of AI-powered code readers has a compact design - 72% smaller than our conventional models - while still providing high-performance reading for a wide variety of codes. The AI and latest decoding algorithms provide stable reading between processes, tracking changes in codes that occur from one process to the next. It is also possible to link code readers between processes for improved reading performance. With these connections, the operating status and current settings of readers on the same network can be viewed together in a list. Automatic focus adjustment and fully automatic tuning make setup easy with the press of a button.

Features

Impressive Imaging Capabilities in an Integrated Design

With a typical camera lens, the corners of the captured image are distorted and essentially unusable for reading. KEYENCE’s newly developed imaging lens makes effective use of the entire area captured by the CMOS image sensor, ensuring readability even in the corners of the image.

- Ultra-compact imaging lens

- New HDR wide CMOS

- Built-in 3-way lighting (direct, polarised, diffused)

Integrated Lens, Lighting, and High-Resolution CMOS

The integrated design provides completely automatic configuration of the best settings with no need to select equipment or adjust settings. The reader automatically selects the optimal lighting conditions for the target.

Reliably Identify Codes

SR-X Drive: A New Decoding Algorithm from KEYENCE

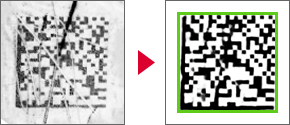

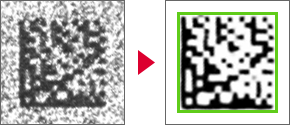

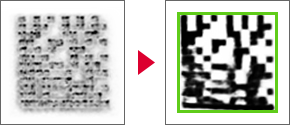

AI filters help read difficult codes. Optimised specifically for code reading, the built-in inference-specific AI chip was created through learning of a database of over 100,000 images. This results in dramatically improved code reading performance.

Stains

Scratches

Rough Backgrounds

Uneven Cell Colour

The SR-5000 Series logistics code reader offers an ultra-wide field of view, ultra-long depth of field, and high-speed reading, resulting in easy installation and operation in logistics environments for reliable capture of codes on fast-moving packages. Stable reading is ensured even when packages of different shapes and sizes are on the same line moving at high speeds, regardless of where the barcode labels are found on the packages. These readers eliminate the need to prepare to align the packages to one side of the conveyor, thereby contributing to reduced costs and a lower risk of malfunction thanks to the simplified conveyor system. While multiple readers were conventionally necessary for reading one side, simply installing one SR-5000 Series reader per side makes it possible to read the codes on labels affixed on the top and sides of packages of different sizes and varying locations. This is possible thanks to the ultra-wide field of view and deep depth of field of the SR-5000 Series.

Features

Ultra-Wide Field of View & Ultra-Long Reading Depth

Reliable reading even for packages of different sizes.

Ultra-High Speed

Stable reading even on high-speed lines exceeding 150 m/min.

Obtain a wider field of view and greater depth of field at a longer range. Work as fast as the targets can move. No experience is required to master the SR-2000 Series. Just install the reader for vastly improved reading range and achieve even better reading stability.

Reading the most difficult 1D and 2D codes is made simple though the introduction of new features including automatic tuning, autofocus, and built-in polarisation. Best-in-class performance is paired with built-in I/O and field network functionality, including EtherNet/IP® and Profinet, to allow for easy integration with any system.

Offers high performance and high speed code reading in a compact body to easily integrate into existing systems. Setup is simple so even new users will readily understand.

Features

Compact Body

The compact body can be mounted in small spaces, expanding the range of applications.

High-Quality, High-Speed Reading

New algorithms provide best-in-class reading capability even when the code is hard to read.

KEYENCE's new BL-1300 Series (3Hi-Digital) models. The first models in this class to use parallel digital processing technology.

Provides high quality reading performance of 1D and 2D codes. Built-in code corrective algorithms mean reliable reading, even when code quality changes due to printing or marking variances.

Long range, 700 scans/sec., laser type barcode readers with Windows® setup software, offers a reading range of up to 47inches.(1200mm)

Half the size, twice the range of other Barcode Readers in its class, built-in PMI function for real time monitoring and reading performance reporting.

LED/CCD type barcode readers using a compact, space-saving design for mounting flexibility and OEM applications.