Flow and Pressure Dual Sensor

FD-EP series

Flow and Pressure Dual Sensor FD-EP series

Flow × Pressure Monitoring Easy to Diagnose Condition of Pneumatic Equipment

- Zero risk of clogging

- Selection is easy

- Predictive maintenance made easy

The compact case of the FD-EP Series houses a flow sensor and a pressure sensor, making it easy to diagnose the status of pneumatic equipment. The specialised application function makes real-time diagnosis and predictive maintenance of cylinders, suction transfer, seating and air blowers easy. The free flowing structure prevents pressure loss, clogging and supports both small and large flows. When selecting the sensor, just choose the one that matches your tube diameter. The high-definition display allows for intuitive operation with no need for an instruction manual. This one device can handle applications in which gases flow forward and backward such as cylinder forward and backward motion and the suctioning and vacuum release during suction transferring.

Features

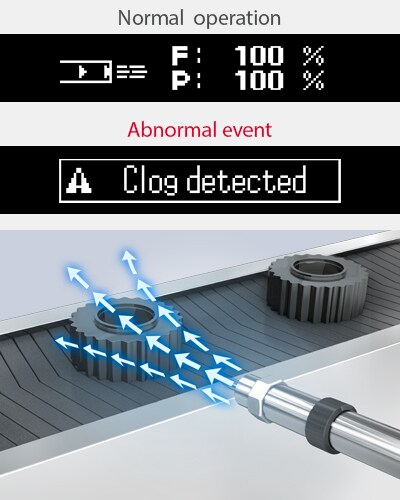

Zero Risk of Clogging

The FD-EP Series has a free flowing structure with no protrusions or obstructions in the flow path. Therefore, there is no need to worry about clogging or pressure loss caused by the flow sensor itself. Enjoy peace of mind throughout the installation process.

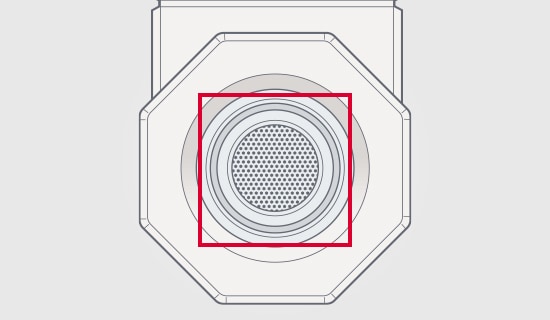

Conventional Unit

Pressure loss and clogging caused due to rectifier mesh plate inside.

FD-EP Series

Free flowing structure

There are no protrusions or obstructions that can cause pressure loss or clogging.

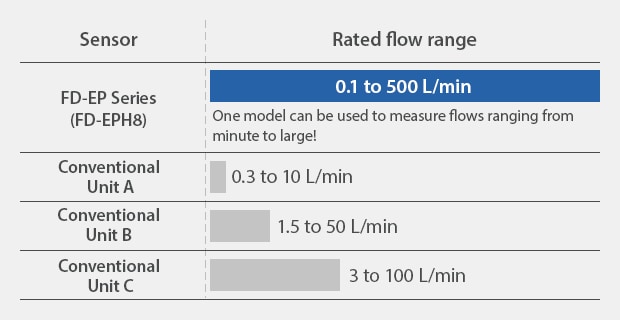

Comparison of rated flow ranges (example with ø8 tube and fluid pressure of 0.4 MPa)

Selection Is Easy

Conventional air flow sensors have a different rated flow range depending on the model, even for the same tube diameter, making it very difficult to find the appropriate model for novel applications. The FD-EP Series can handle flows ranging from minute to large, eliminating the need to worry about the rated flow. Choosing a product is as easy as selecting the tube diameter.

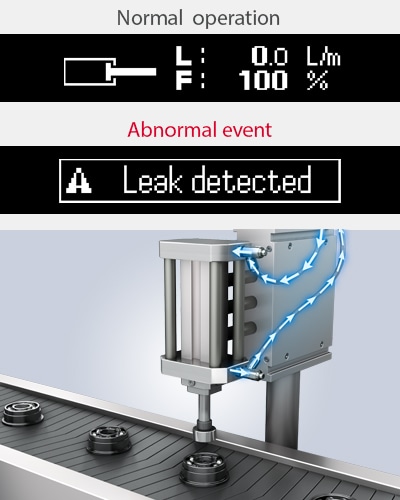

Predictive Maintenance Made Easy

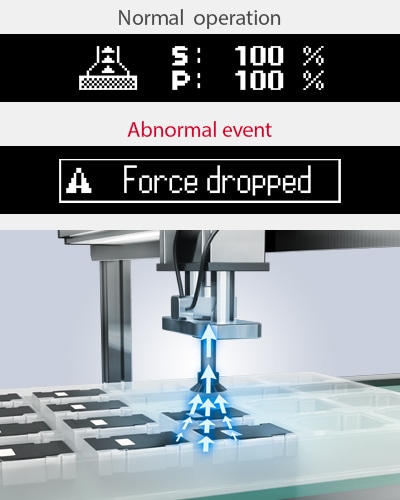

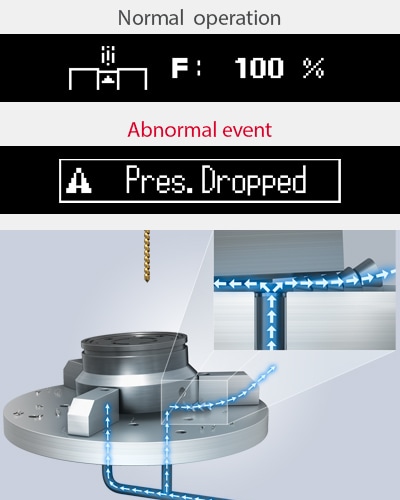

The FD-EP Series simultaneously measures flow and pressure and processes them in a dedicated application mode* to diagnose issues with pneumatic equipment that are often conventionally managed by operator expertise. Equipment productivity improvement can be realised by capturing the condition of pneumatic equipment in real-time and performing predictive maintenance.

*Some pneumatic equipment may not be compatible depending on its specifications. Contact your KEYENCE representative for more details

Cylinder Status Monitoring

Suction Conveyance

Seating

Air Blowing