Industrial Laser Marking Systems / Laser Markers

Laser Marking vs Dot Peen Marking Machines : An Overview of Two Popular Marking Technologies

-

Tags:

- Laser Marking , Aerospace , Metal

Marking is a necessary part of many industries and businesses, as it allows businesses to identify and trace products throughout the supply chain lifecycle. Two well-known marking methods are laser marking and dot peen marking. However, these two technologies are not created equal. In this article, we’ll discuss laser marking vs dot peen marking and how to make the best marking choice for your business needs.

- Laser Marking

-

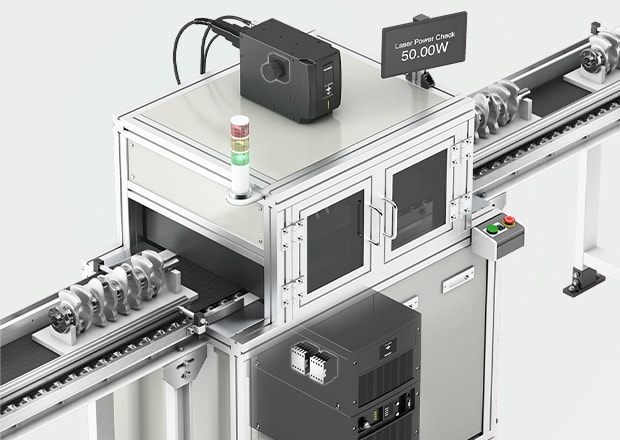

A laser marking machine is an innovative technology that marks objects with focused light. The process begins with the laser machine’s oscillator releasing a high-energy light (laser) which is then scanned by a mirror. The mirror and the focusing lens then work together and focus the beam on the target. Then, the beam hits the target and discolours the surface. In this process, heat absorption is the channel for marking.

Laser markers are popular across a diverse range of materials, including :When it comes to processing, a laser marking machine creates the following :

- Text

- Logos

- Barcodes

- 2D Codes

Material Selection

| Material name | UV Laser Marker MD-U Series |

Hybrid Laser Marker MD-X Series |

Fibre Laser Marker MD-F Series |

CO2 Laser Marker ML-Z Series |

|

|---|---|---|---|---|---|

| Resin | EP (epoxy resin) | very good | very good | good | good |

| ABS (ABS resin) | very good | very good | good | possible | |

| PBT | very good | very good | good | possible | |

| PA | very good | good | possible | good | |

| PC (polycarbonate) | very good | good | good | good | |

| PP (polypropylene) | very good | good | possible | good | |

| PE (polyethylene) | very good | good | possible | good | |

| PET | very good | not possible | not possible | very good | |

| PPS | very good | good | possible | good | |

| PS (polystyrene) | very good | good | possible | good | |

| PI (polyimide) | very good | possible | possible | possible | |

| PVC (polyvinyl chloride) | very good | good | good | very good | |

| Glass epoxy | very good | good | good | good | |

| Metal | SUS (stainless steel) | good | very good | very good | not possible |

| Fe (iron) | good | very good | very good | not possible | |

| Al (aluminium) | good | very good | very good | not possible | |

| Ni (nickel) | very good | good | good | not possible | |

| Cu (copper) | very good | good | possible | not possible | |

| Au (gold) | very good | good | possible | not possible | |

| Other | Ceramic | very good | good | good | good |

| Si (silicon) | very good | good | possible | possible | |

| Paper | good | good | good | very good | |

| Rubber | very good | very good | very good | very good | |

| Glass | good | not possible | not possible | very good | |

| Wood | possible | possible | possible | very good |

Scroll

*The evaluations for the symbols given in the table vary depending on the state and additives of the target as well as on the set conditions. Use this information as typical examples

- Dot Peen Marking

-

Dot peen marking machines, also known as pin marking, are in a subcategory of engraving. A dot peen marking machine uses a pin to carve into a product. The pin, also known as a stylus, is made of carbide or diamond and cuts small but deep dots to form a design. These styluses are either handheld or automated, which differs from the strictly automated laser marking machine. Since the process involves carving, the result is an indented design, unlike the surface discolouration of a laser marking machine.

A dot peen marking machine relies on friction to sculpt designs, meaning that dot peen marking is limited to sturdy materials. The best success is with hard metals or plastics. On these materials, dot peen marking marks :- Logo

- Text

- Number

- 2D Code

Discover more about this product.

Click here to book your demo.

Differences Between Laser Marking and Dot Peen Marking

When Should You Choose Laser Marking?

If you’re manufacturing for an industry that has products that shouldn’t be contaminated with outside materials, such as the food, pharmaceutical, or medical device industry, choosing a laser marking machine is the best choice. A laser marking machine discolours the surface for a permanent mark, unlike dot peen marking, which creates an indent that collects contaminates like dust.

On a similar note, a laser marking machine is also optimal if you’re marking sensitive materials like glass, plastic, paper, rubber, or cardboard. Laser markers use pointed heat absorption for marking, which doesn’t compromise the rest of the product.

When Should You Choose Dot Peen Machines?

Choosing a dot peen marking machine must only be on a strong product that is resistant to friction and unaffected by contaminants. Examples of products that are okay for a dot peen machine include thick pipes, tools, or tubes.

We’re here to provide you with more details.

Reach out today!

Choosing the Right Marking Technology : A Comprehensive Comparison of Laser Marking and Dot Peen Marking Machines

Exploring the Pros and Cons of Laser Marking for Industrial Applications

- Pros

-

- No Surface Damage

-

A laser marking machine uses high-energy light to discolour a product through heat absorption. This heat absorption can be set up so that it has no surface damage.

- Diverse Marking Ability

-

Laser marking machines achieve a diverse range of marks across industries. Industries in which laser markers are used include :

- Permanent and High Contrast

-

Since the laser marking machine uses heat absorption for marking, all marks are permanent and high contrast. Permanency and high contrast are particularly critical for industrial applications like traceability designs, which must be read by machines and/or humans.

- Cons

-

- High Upfront Investment

-

Laser markers are versatile, user-friendly, and create fantastic marks, but it comes at a price. Although laser markers are a worthy long-term investment, a laser marker may not be the best choice if your budget is slim for a short-term project.

Dot Peen Marking Machines : Benefits and Drawbacks for Industrial Product Traceability

- Benefits

-

- Deep Marks

-

A dot peen marking machine uses electromagnetic strikes for carving designs. Because of the cutting nature, the marks are deep and sturdy.

- Good on Thick Materials

-

The intense nature of a dot peen marking machine is strong enough for any thick material. Industries like aerospace, defense, metalworking, and oil and gas may benefit from a dot peen machine.

- Portable

-

Dot Peen marking machines are small and sometimes handheld, so they can be brought to a production site. This is particularly beneficial for traceability marks on large parts that can’t be transported to production sites easily.

- Cons

-

- Not Always Efficient

-

With some dot peen marking machines being handheld, it's not the most efficient choice. Handheld dot peen marks take time, energy, and extra costs. It takes time and money for an employee to receive training on using a dot peen marker. Then, the employee must do it by hand, which requires manual effort and frequent breaks in production.

- Damages Some Products

-

Dot peen machines use a stylus to strike a material, which can be damaging. Using a dot peen on fragile materials damages the product and causes defects.

We’re here to provide you with more details.

Reach out today!

Choosing the Right Marking Technology : Factors to Consider When Deciding Between Laser Marking and Dot Peen Marking Machines

Material Type

As mentioned above, dot peen marking machines require a particular type of material to work on.

Use a laser marking machine for these materials :

- Metal

- Glass

- Rubber

- Ceramic

- Resin

- Plastic

- Cardboard/paper

Use a dot peen machine for these materials :

- Hard metal

- Hard plastic

Marking Speed

Dot peen machines vary in speed, as they can be handheld or automatic. A laser marking machine is always automated and moves quickly through the production line.

Surface Finish

If you’re looking for a clean surface finish that does not have any processing flaws, choose a laser marking machine. KEYENCE’s marking machines use 3-axis technology to autofocus and create uniform marks across the entire product that are clean and precise.

We’re here to provide you with more details.

Reach out today!

Ready to See the Effectiveness of Laser Marking?

At KEYENCE, we offer free trial equipment so you can test our laser marking machines for your business needs. We’re ready at any level of your process to help you, from the design and research stage all the way to after-product adoption. Request a trial today!

Discover more about this product.

Click here to book your demo.

![MARKING APPLICATIONS - Component Traceability in Automotive Manufacturing [Engine Compartment]](/img/asset/AS_46961_L.jpg)